Recently viewed

Colored resin changes how your 3D prints look and feel from the first layer. At Siraya Tech, our colored resin collection is built for makers who want sharp detail, strong parts, and rich color without extra painting.

Each resin is tuned for smooth curing, steady exposure, and reliable results across LCD and DLP printers. You get color that looks finished straight off the build plate, plus performance you can trust for real projects.

Color that Prints Clean and Stays Sharp

A good colored resin should do more than look nice. It should protect details and cure evenly. The pigments are blended to avoid light bleed and over-curing. This keeps edges crisp and surfaces smooth, even on small features.

Consistent Color From Top to Bottom

You get uniform tone across the whole print. No patchy layers or faded spots after curing.

- Clean edges on miniatures and models

- Smooth surfaces with less post-work

- Predictable exposure times across colors

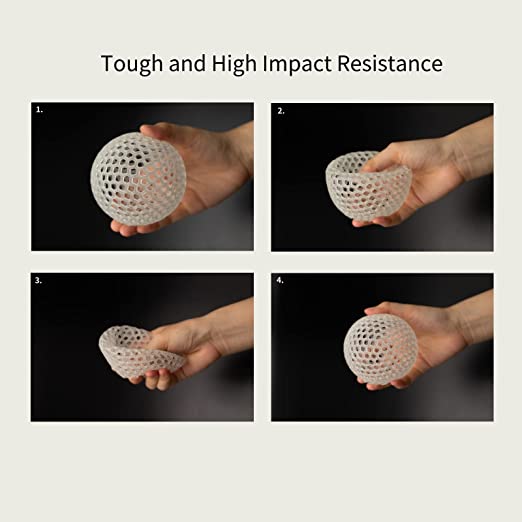

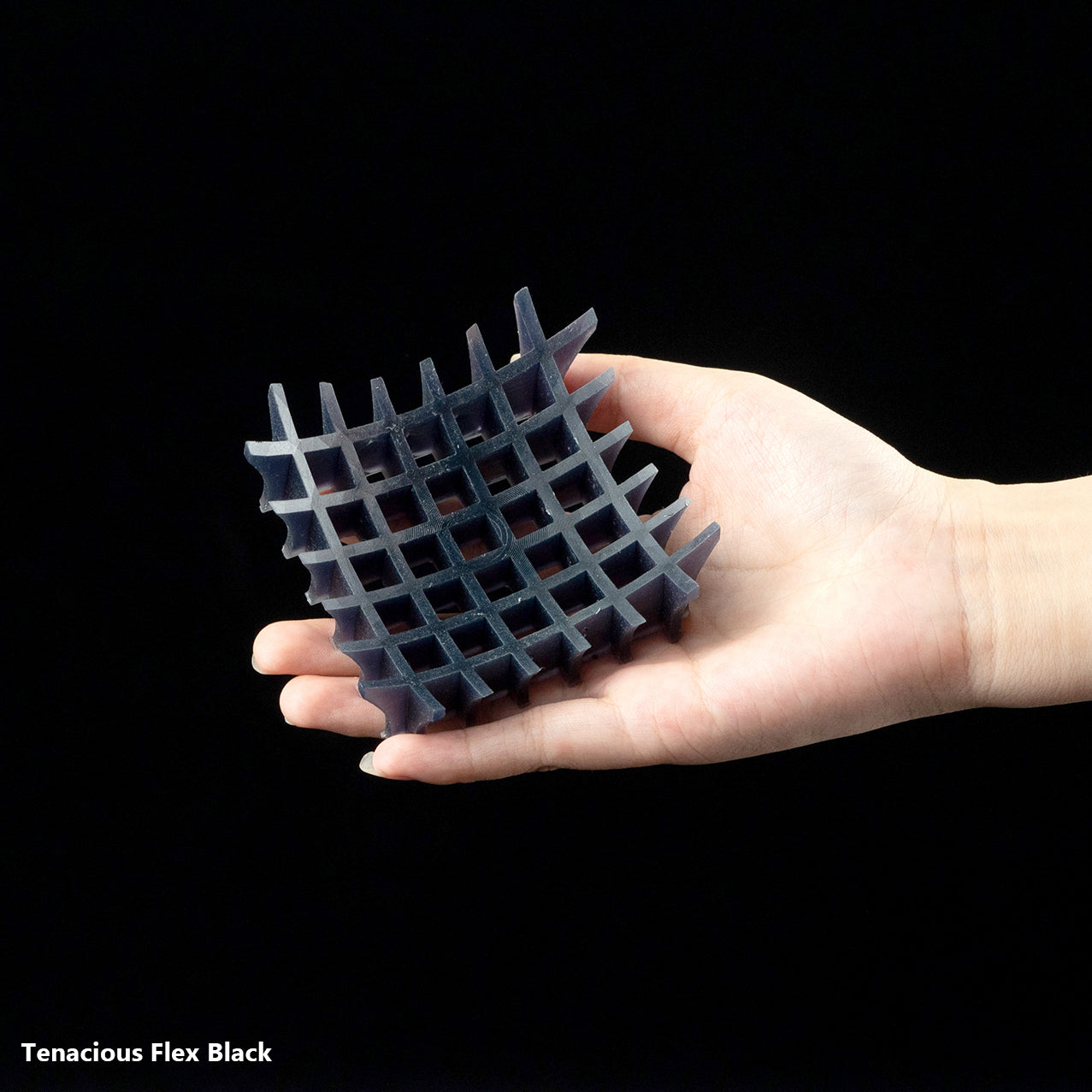

Built for Strength, Not Just Looks

Colored resin at Siraya Tech is made for real use, not display only. Many formulas focus on impact resistance and flex where it matters. Prints feel solid, not brittle.

Stable Prints That Hold Shape

Parts keep their size and detail during curing and after. This matters for tight fits and moving parts.

- Better layer bonding for daily handling

- Reduced cracking during post-cure

- Suitable for prototypes and end-use parts

Easy Workflow for Everyday Printing

Colored resin should make printing simpler, not harder. The resin pours well and releases cleanly from the build plate. Washing and curing stay simple.

Friendly for Tuning and Mixing

You can fine-tune settings or blend with other resins to adjust strength or flexibility without losing color control.

- Consistent viscosity for stable prints

- Less trial and error when dialing settings

- Works well on most resin printers

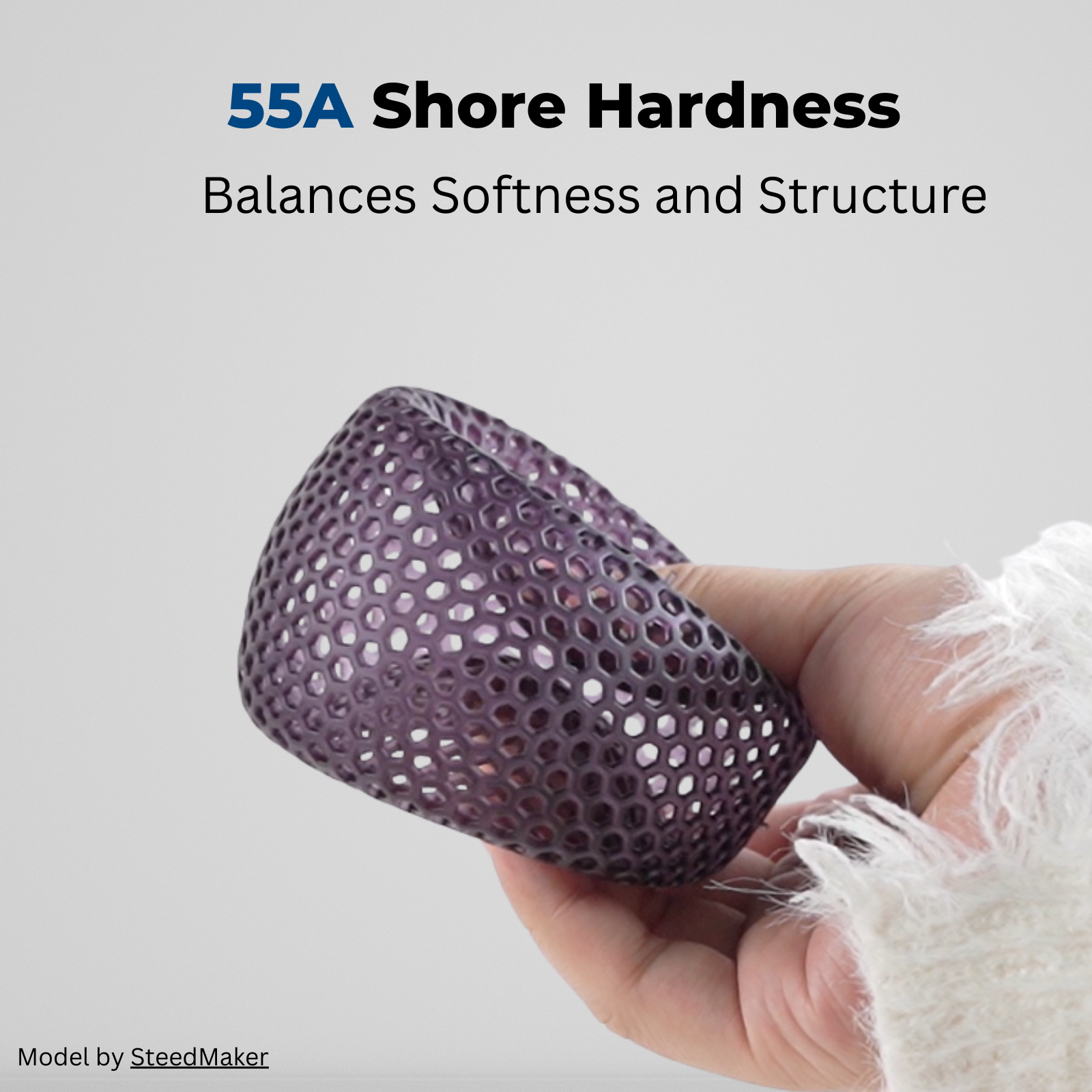

Color Choices That Fit Real Projects

Different projects need different resin behavior. Color is just one part of the story. You can choose resins that bend slightly, stay rigid, or handle heat, all while keeping strong color.

Designed for Creative and Technical Use

Great for figures, tools, jigs, housings, and display parts that still need durability.

- Useful for models, props, and prototypes

- Good surface finish straight from printing

- Supports sanding, drilling, and coating

Explore More Materials You Might Like

If you work across resin and filament, these collections pair well with colored resin projects:

- Flexible Resin 3D Printing – Ideal for parts that need bend, grip, or impact absorption.

- Strong Filament – Built for durable FDM parts that match the toughness of resin prints.

- 1.75mm Filament – Reliable diameter control for clean, consistent FDM printing.

- Heat Resistant Filament – Designed for parts that face higher temperatures and stress.

FAQs on Colored Resin

How to use coloured resin?

Colored resin is used like standard UV resin but needs proper mixing before printing. Shake the bottle well so pigments are evenly spread, then pour it into the vat. Use exposure settings suited to the color, since darker shades often need slightly longer curing times.

Does the color of resin matter?

Yes, color affects how light passes through the resin during curing. Dark or opaque colors can block light more than light or clear ones. This means exposure times may change, but print quality can stay high with the right settings.

Can you put too much pigment in resin?

Too much pigment can cause weak curing and soft or brittle prints. Excess pigment blocks UV light and prevents layers from fully hardening. Using pre-colored resin avoids this issue because pigment levels are already balanced.

What happens if you don't sand between coats of epoxy?

If you skip sanding, the next coat may not bond well to the surface. This can lead to peeling, uneven texture, or visible lines. Light sanding helps each layer stick better and look smoother.

Is colored resin good for functional parts?

Yes, colored resin can be used for functional parts if the formula supports strength and durability. Many colored resins are designed to handle stress, light impact, and daily use. Always match the resin type to the job, not just the color.