Recently viewed

Clear resin shows every detail, from sharp edges to tiny textures. It cures quickly, sands well, and has a glass-like finish when finished correctly.

At Siraya Tech, our clear resin blends prioritize optical clarity, strong layer bonding, and ease of post-processing for both display models and workhorse parts.

Clear Resin Clarity That Looks Like Glass

Short cure times and low haze keep parts bright and readable. You get crisp edges, smooth flats, and a clean base for polishing or tinting.

- Low-haze formula keeps features visible.

- Balanced viscosity reduces micro-bubbles in the vat.

- Clean cure chemistry helps parts stay transparent after wash.

Keeping Transparency After Cure

Use fresh isopropyl alcohol for the final rinse and avoid prolonged over-curing. A short, even UV pass locks clarity without fogging.

Clear Resin Strength For Daily Use

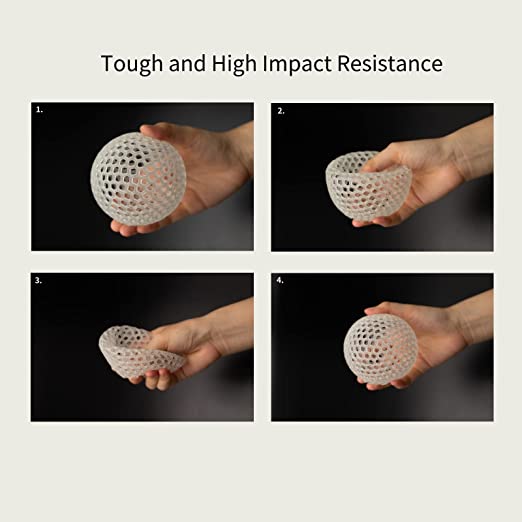

Prints feel solid and resist small drops and flex. Tough blends protect thin walls and small clips.

- Toughened matrix improves impact resistance.

- Strong layer adhesion supports snap fits and tabs.

- Heat-aware options keep shape under warm lights.

When You Need Function And Looks

For functional prototypes, pick a formulation with higher toughness or heat tolerance. Keep the look while gaining durability.

Clear Engineering Performance For Real Work

This clear, tough engineering resin balances strength and detail for functional parts that still look premium. High hardness and robustness enable parts to maintain tolerances and withstand repeated use.

It’s also biocompatible under ISO 10993-10, which is useful for skin-contact prototypes when processed correctly.

- Tough engineering formulation with excellent mechanical properties

- High hardness for wear-prone features and precise fits

- ISO 10993-10 biocompatibility for appropriate skin-contact prototypes*

-

Prints finish clean and resist chipping on thin walls

*Always validate end-use safety and post-processing for your application.

Where It Fits Best

Use it when you need clear parts that work hard, not just look good. Great for shop floors, labs, and demo rooms.

- Engineering Prototypes — test fits, moving hinges, and snap-fits

- Mechanical Aids — spacers, brackets, light guides with function

- Fixtures And Jigs — inspection windows and alignment tools

- Medical Devices — housings and mockups for evaluation (verify compliance)

Explore Related Collections

- Castable Resin — Burnout-ready blends for clean trees and detail-rich jewelry.

- 3D Model Resin — High detail and smooth surfaces for miniatures and display models.

- Engineering Resin — Tough, heat-aware options for working prototypes and fixtures.

FAQs About Clear Resin

What Is Clear Resin Used For?

Clear resin is used in SLA or MSLA 3D printers to make see-through parts with fine detail. It’s great for light pipes, fluid channels, lens mockups, display models, and any prototype where you need to see internal features. Designers use it to check fit and flow, then finish it with sanding and clear coats for higher optical clarity. It also works well for art pieces and product demos.

How Do I Keep Clear Prints From Yellowing?

Limit UV exposure by storing parts away from sunlight and strong indoor UV. Post-cure only as long as needed and at moderate temperatures to avoid overcuring. Rinse thoroughly, dry fully, then apply a UV-resistant clear coat to add protection. Keep parts clean and away from high heat during use and storage.

What is the Difference Between Epoxy Resin and Clear Resin?

Epoxy resin is a two-part casting or coating material that cures by mixing resin and hardener. “Clear resin” for 3D printing is a UV-curable photopolymer used in SLA or MSLA printers that cures layer by layer with light. Epoxy is ideal for coatings, encapsulation, and casting; 3D printer resin is designed for high detail and fast curing in printers. They are not interchangeable in printing hardware.

Can I Warm Or Degas Resin Before Printing?

Yes. Slightly warming resin to about 25–30 °C lowers viscosity and helps it flow and level better. Degassing in a vacuum chamber can remove bubbles for sharper details, especially with thick or highly filled resins. Always follow the manufacturer’s safety guidance and avoid overheating.

What makes Siraya Tech Clear Resin Stand Out?

Siraya Tech offers clear resins known for crisp details and reliable curing, and their Blu line is valued for strength when you need tougher parts. Blu is a tough engineering resin with excellent mechanical properties, high hardness, and strong impact performance for tools and functional prints. It is tested for biocompatibility under ISO 10993-10, which covers irritation and skin sensitization. This combination of durability, printability, and validated safety testing makes it a solid choice for demanding applications.