Recently viewed

Black resin is the go-to choice when you want bold color, crisp details, and parts that look finished straight off the build plate. At Siraya Tech, our black resin collection is built for makers who care about accuracy, strength, and repeatable results.

Our collection brings together tough resin, flexible resin, ABS-like resin, castable resin, and high-temperature resin in black. You get control, durability, and professional-looking prints without fighting failed layers or soft details.

Deep Black Color That Makes Details Pop

Rich black resin is not just about looks. It improves contrast, hides layer lines, and makes fine features easier to see and clean.

Cleaner Details You Can Actually See

Black resin enhances edges and textures, making small features stand out during printing and post-processing. The surface comes out smooth and even, reducing sanding and painting time.

- Sharp edges and clear text

- Less visible layer lines

- Ideal for display models and functional parts

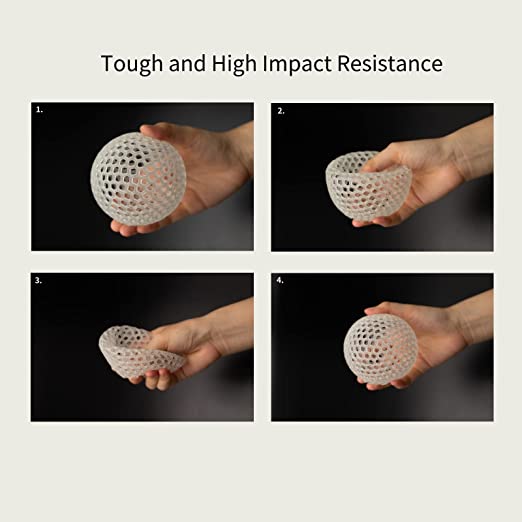

Tuned for Strength, Not Just Looks

Siraya Tech black resin is designed for real use, not fragile shelf prints. You get toughness, impact resistance, and reliable layer bonding. These resins resist cracking and chipping under daily handling and light stress.

Consistent Curing for Solid Layers

Even exposure helps layers bond well and reduces weak spots.

- Strong prints with less brittleness

- Better resistance to drops and pressure

- Reliable results across long print jobs

Smooth Printing With Fewer Failures

Black UV resin can be tricky, but this collection is formulated for stable printing and predictable exposure behavior. Balanced pigmentation helps avoid undercured cores and soft surfaces.

Printer-Friendly Flow and Viscosity

Resin spreads evenly during printing, supporting complex shapes.

- Reduced risk of layer separation

- Fewer failed prints

- Works well with common MSLA and LCD printers

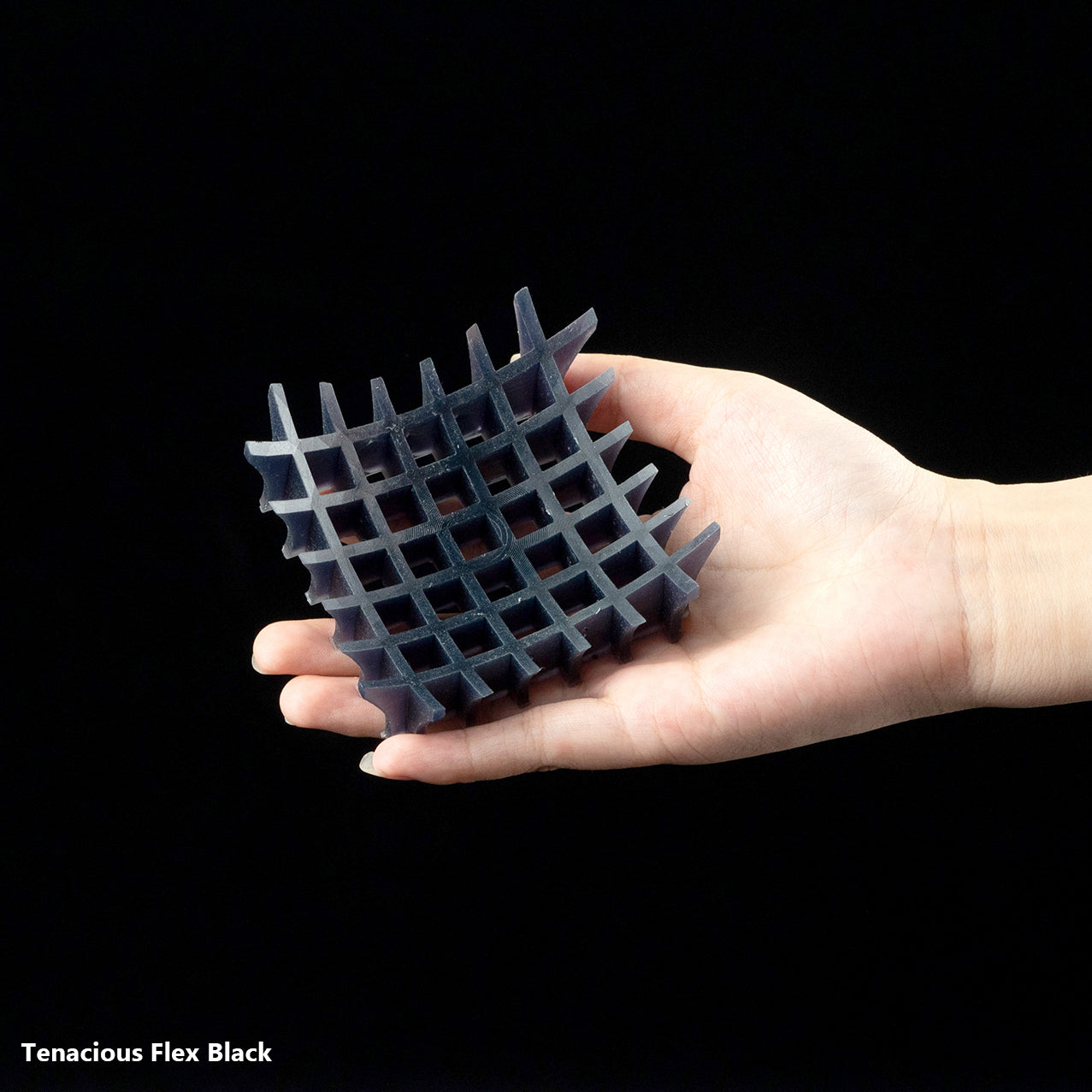

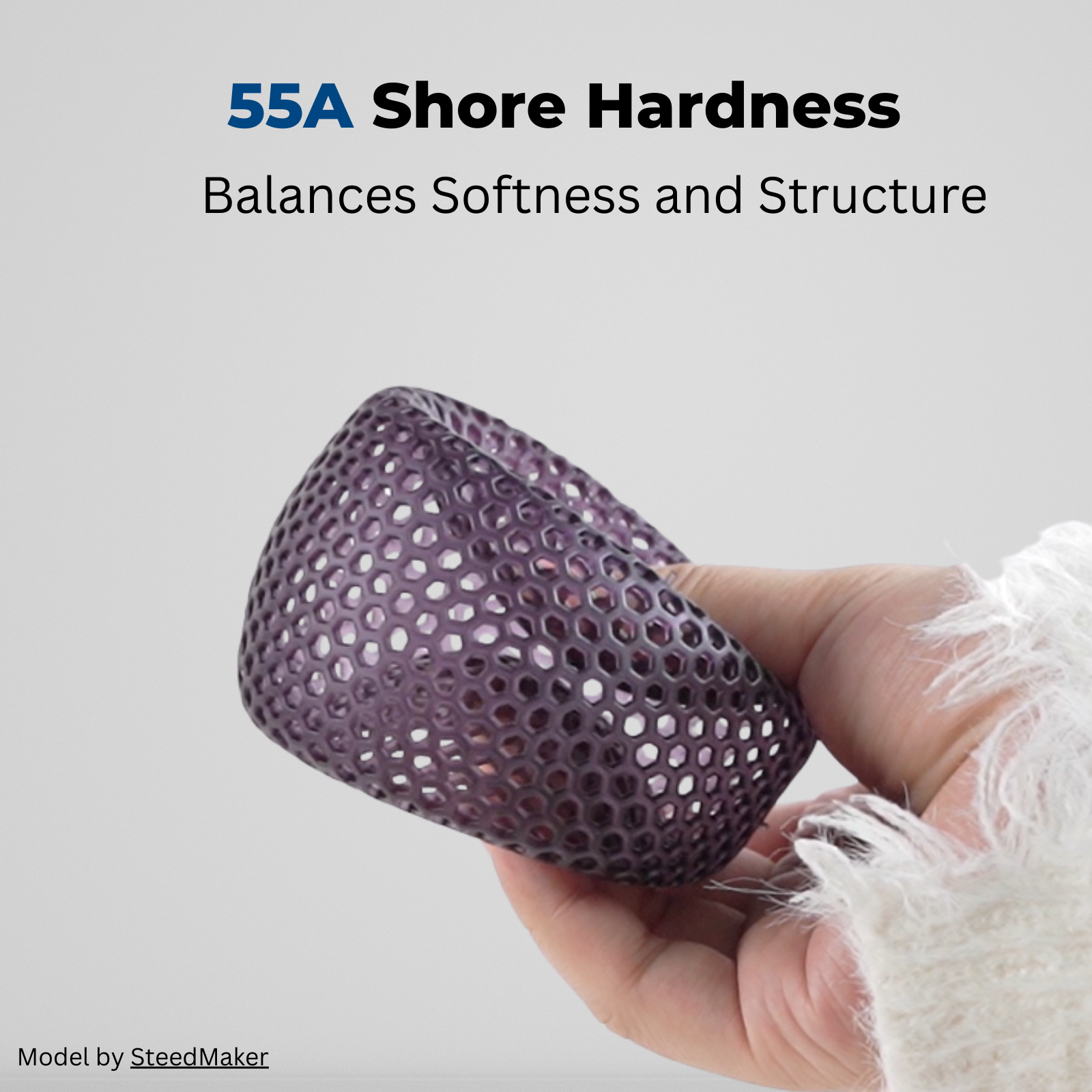

Options for Flexible, Tough, or Heat-Ready Prints

Not all black resin is the same. This collection covers different use cases so you can match the resin to your project. Great for parts that need bend, grip, or shock absorption.

Rigid and High-Temp Blends

Ideal for jigs, fixtures, and parts exposed to heat or stress.

- Flexible black resin for durability

- ABS-like resin for strength and ease

- High-temperature resin for demanding uses

Easy Post-Processing, Better Results

Black resin prints should be simple to clean and cure. These materials are made to save time after printing. Supports washing, curing, drilling, and sanding without crumbling.

Reliable Curing Without Guesswork

Predictable results with proper exposure settings.

- Clean surfaces after washing

- Less risk of sticky prints

- Ready for use or finishing faster

Explore More Siraya Tech Collections

If you are building across different printers or materials, these collections pair well with black resin projects:

- PLA Filament for 3D Printing– Easy-to-print filament for fast prototypes and everyday models.

- Flexible Resin 3D Printing – Resin materials made for bend, grip, and impact resistance.

- Strong Filament– Filaments designed for durable, load-bearing FDM parts.

- Heat Resistant Filament– Materials built to hold shape under higher temperatures.

FAQs on Black Resin

Does black resin need more exposure?

Yes, black resin usually needs slightly longer exposure times. Dark pigments absorb more UV light, so less light passes through each layer. Increasing exposure helps ensure layers cure fully and bond well without soft spots.

What happens if you overcure UV resin?

Overcuring makes resin parts brittle and less flexible. Details can blur, and thin features may crack under stress. It can also cause surface discoloration or make post-processing harder.

Is black resin toxic?

Liquid black resin is not safe to touch or inhale before curing. It can irritate skin and eyes, so gloves and ventilation are important. Once fully cured, the resin is generally safe to handle.

Do you have to preheat resin?

Preheating is not required, but it helps in cooler rooms. Warm resin flows better and cures more evenly, which can reduce print failures. A room temperature range around 20 to 25°C works well for most prints.