Recently viewed

Stop printing rigid plastic. Siraya Tech Bendable 3D Printing Filament delivers elastic, stretchable parts that bend thousands of times without cracking or breaking.

Whether you're prototyping phone cases, designing wearable gear, engineering industrial gaskets, or building custom sporting equipment, bendable filaments combine the durability of thermoplastics with the flexibility of rubber.

Choose from industry-leading TPU, next-generation PEBA, and specialty TPE options—all engineered to maximize elongation, rebound, and real-world reliability.

- Up to 600% Elongation: Parts stretch and return to shape without permanent deformation.

- Superior Impact Resistance: Absorbs shock and vibration without shattering or cracking.

- Chemical & Oil Durability: Resists sweat, oils, fuels, and environmental degradation.

- Extreme Fatigue Resistance: Withstands 20,000+ compression and flex cycles without failure.

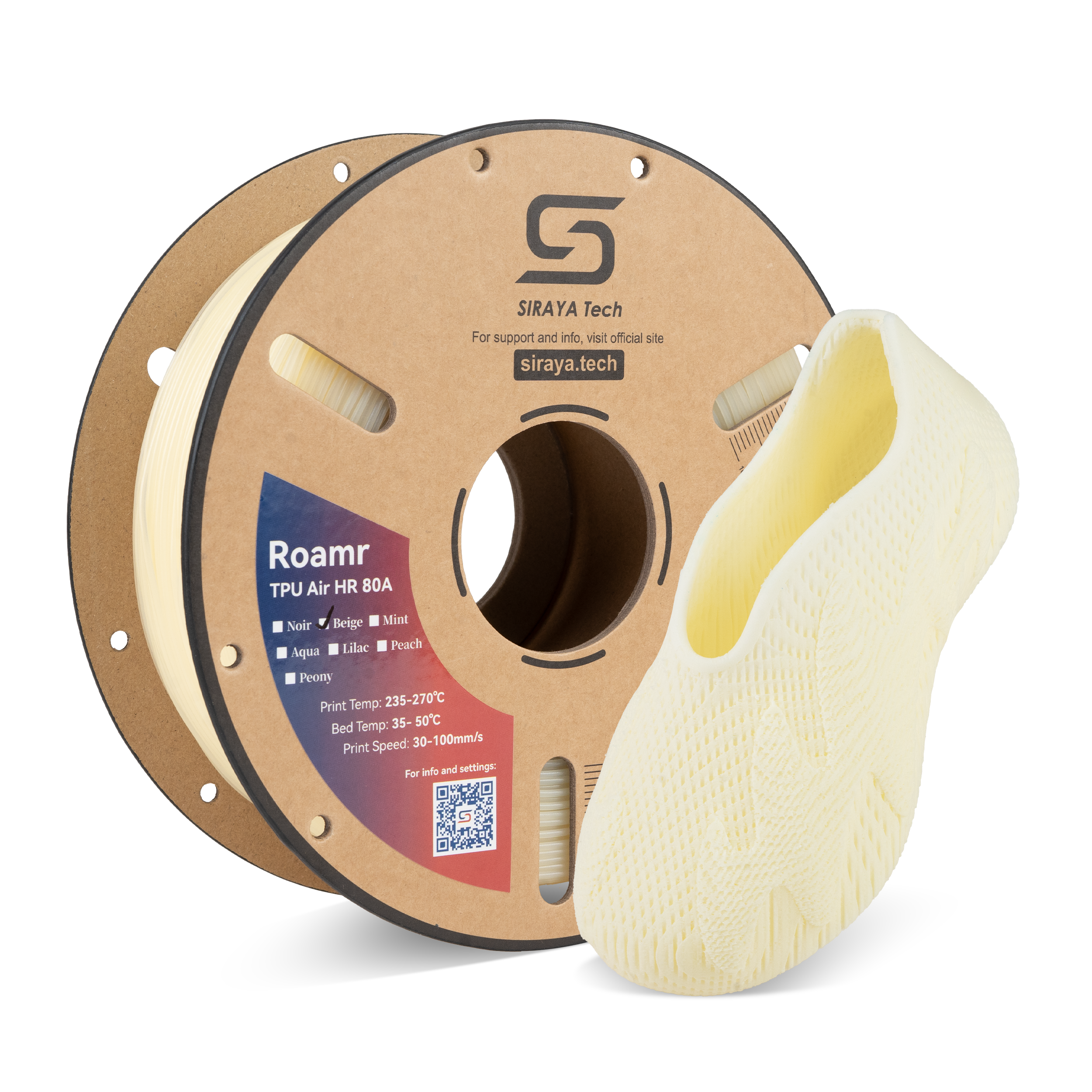

- Shore Hardness Range: 64D to 95A for custom stiffness (softer for grips, firmer for seals).

Why Choose Bendable Filament?

Printing with bendable materials opens up a new world of functional possibilities.

- Unbreakable Durability: The magic of materials like TPU filament is their ability to absorb energy. You can drop, crush, or hammer these prints, and they will simply deform and recover. This makes them perfect for drone bumpers and protective cases.

- Soft Touch Finish: For wearables, stiffness is the enemy. Our soft 3D printer filament conforms to the body, making it ideal for watch bands, shoe insoles, and cosplay props that need to move with you.

- Chemical Resistance: Many of our flexible filaments are resistant to oils and greases, making them excellent for printing custom gaskets and automotive seals that rigid plastics can't seal.

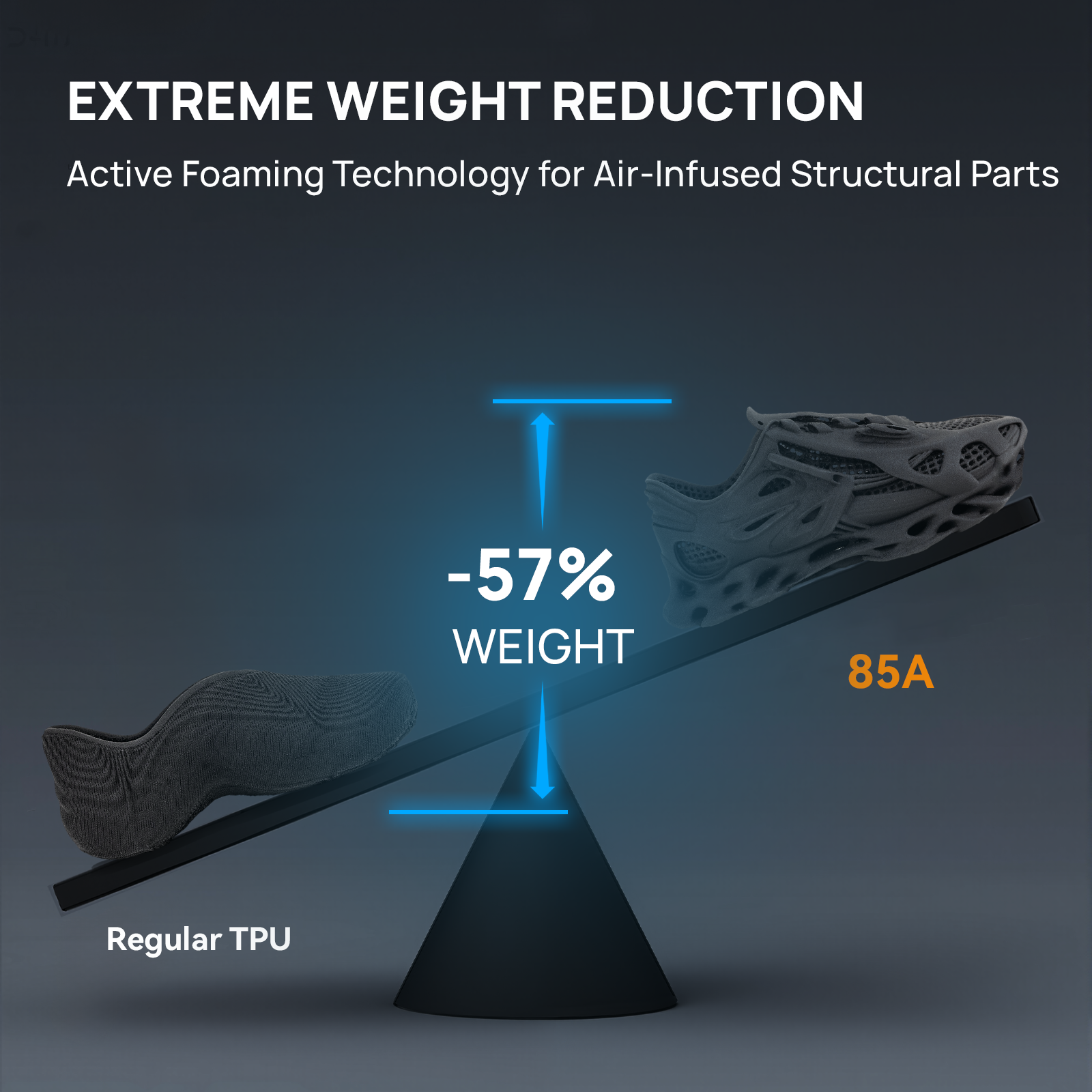

Flexible Material Properties: Understanding Elongation & Elasticity

Bendable filament performance hinges on two critical metrics: how far it stretches (elongation at break) and how completely it returns to its original shape (elastic rebound).

Unlike rigid plastics that snap when bent, bendable materials flex, absorb energy, and bounce back.

Maximum Elongation & Stretch Capacity

Elongation at break measures how far a material stretches before tearing. Standard rigid filaments like PLA have 1-6% elongation—they're brittle and fail instantly under stress. Bendable filaments dramatically exceed this:

- TPU 95A: 450-600% elongation. The material can be pulled to 6 times its original length before tearing.

- PEBA 90A: 450-550% elongation with superior rebound. PEBA bounces back faster and more completely than comparable TPU.

- TPE 70A-80A: 800-900% elongation. Maximum stretchiness; ideal for ultra-soft grips, bands, and wearables.

In practical terms, a TPU phone bumper can absorb a 3-foot drop, compress 40% on impact, then immediately snap back to shape. A rigid PLA bumper would shatter.

Elastic Rebound & Energy Return

Not all elongation is equal. A stretchy material can also be "dead"—it elongates but doesn't bounce back. Siraya Tech's bendable filaments prioritize rebound: the ability to return to original shape and size after deformation.

- PEBA: 70-85% rebound. A ball dropped onto PEBA bounces to nearly full height on the second bounce, delivering lifelike athletic performance.

- TPU: 45-55% rebound. Good for impact absorption, but less "lively" than PEBA.

- TPE: 30-40% rebound. Excellent for dampening vibration; used in shock absorbers and isolation mounts.

The difference: PEBA excels at sports equipment (basketballs, shoe insoles). TPU dominates protective gear (phone cases, helmets). TPE owns industrial dampening (machinery vibration isolation).

FAQs Bendable 3D Filament

What is the best bendable filament for beginners?

For beginners, TPU 95A is the best choice. It is bendable but stiff enough to feed smoothly through most 3D printers without jamming. It offers a great balance of flexibility and printability.

Can I print bendable filament on an Ender 3?

Yes, you can print TPU 95A on an Ender 3 with a stock Bowden setup. However, for softer bendable filaments like 85A, you may need to upgrade to a direct drive extruder or print extremely slowly.

What is the difference between 95A and 85A filament?

The number refers to "Shore Hardness." 95A is like a shopping cart wheel—tough and semi-flexible. 85A is softer, more like a shoe sole. The lower the number, the more bendable and "squishy" the filament is.

Does bendable filament warp?

Generally, TPU and TPE warp less than materials like ABS. However, because they are flexible, they can peel off the bed if the first layer isn't squished down well. We recommend using a heated bed (40-60°C) and a glue stick for insurance.

Is bendable filament waterproof?

Yes, most TPU and TPE filaments are water-resistant and do not degrade easily in moisture, making them great for outdoor parts or seals. However, the print itself is only waterproof if your layer adhesion is perfect.