You want to print a part that lasts. You want it to be strong. You want it to handle the real world. Naturally, you type "ABS" into the search bar. It is the plastic used in LEGO bricks, car dashboards, and power tool housings. It is legendary for a reason.

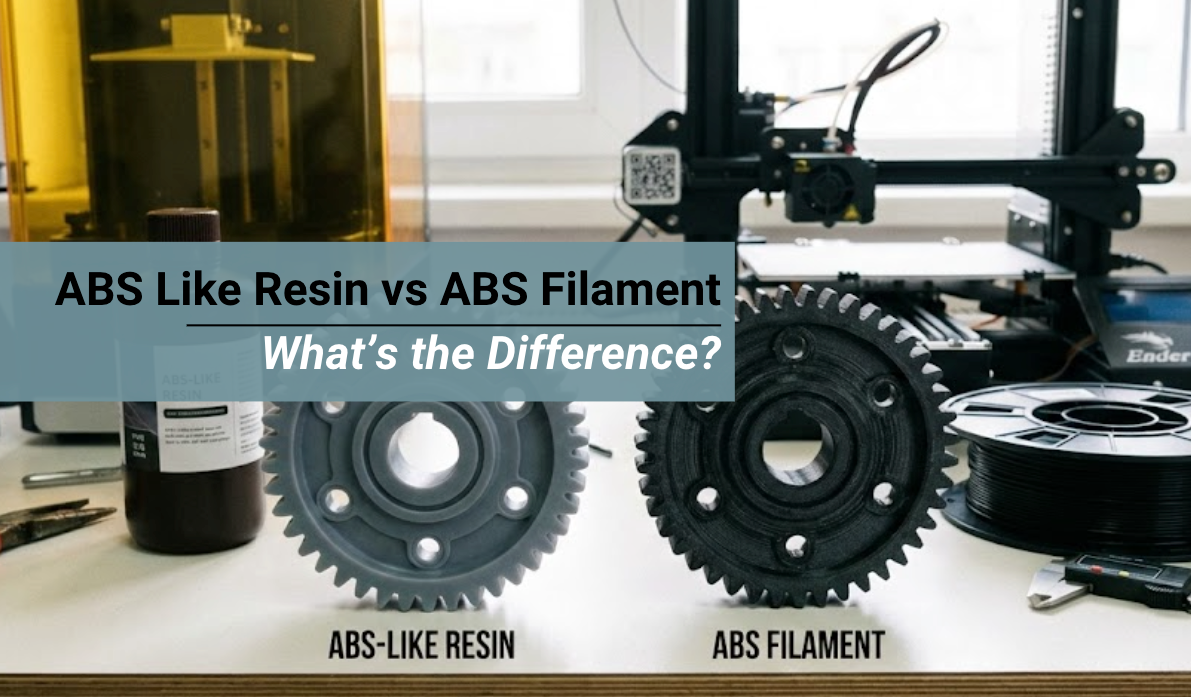

But then you hit a wall of confusion. The search results show you two completely different things. One is a spool of plastic wire that looks like weed-whacker line. The other is a black liquid in a bottle that resembles motor oil. Both of them say "ABS" on the label. Both claim to be tough. But they are chemically worlds apart.

This is the classic debate of FDM (Fused Deposition Modeling) versus SLA (Stereolithography). One melts plastic with heat. The other cures plastic with light. One is famous for warping and frustration. The other is famous for sticky messes and stunning detail.

In this guide, we are going to break down the battle of abs like resin vs abs filament to help you decide which material actually belongs in your workshop.

The Quick Comparison

- ABS Filament (Real ABS): This is the real deal. It is best for functional parts that need high heat resistance (100°C) and durability. It is harder to print because it likes to warp off the bed.

- ABS-Like Resin: This is a simulation. It is best suited for high-detail miniatures or prototypes that need to look injection-molded. It mimics the tensile strength of ABS but usually cannot handle the same high heat.

- The Big Difference: ABS Filament is a thermoplastic that melts. ABS-Like Resin is a thermoset polymer that burns if heated too high.

- Workflow: Filament is cleaner but requires an enclosed printer. Resin requires washing and curing but offers perfectly smooth surfaces.

What is ABS Filament?

The Pros of Filament

- True Heat Resistance: This is its superpower. ABS does not get soft until it hits about 100°C. You can leave an ABS print on your car dashboard in the middle of a Texas summer, and it will be fine. You can put it in the dishwasher. It is built for heat.

- Impact Durability: ABS has "give." If you hit it with a hammer, it might dent or bend white (stress marks) before it actually snaps. It is ductile, not brittle.

The Cons of Filament

- Warping: ABS hates to cool down. As it cools from 240°C to room temperature, it shrinks significantly. This shrinking pulls the corners of your print up, peeling them off the build plate. You almost always need an enclosure to keep the air warm around the print.

- Layer Lines: Because the printer lays down lines of plastic, the surface is rough. It looks like a 3D print. To make it smooth, you have to sand it heavily or use acetone vapor smoothing.

- Fumes: Melting ABS releases styrene gas. It smells like burning plastic or Styrofoam. You definitely need good ventilation.

Shop ABS Filaments Now

Explore MoreWhat is ABS-Like Resin?

Here is the secret that marketing teams don't always tell you: "ABS-Like" resin contains zero actual ABS plastic. It is a marketing term. It is a photopolymer (typically epoxy- or urethane-based) formulated to match the tensile strength and flexibility of ABS.

Standard resins are often brittle like glass. If you drop a standard resin mini, an arm snaps off. ABS-like resins, such as our Siraya Tech Fast or Blu series, have added toughness modifiers. They will bend slightly before breaking, just like real plastic.

👉 To understand the variety of liquid plastics available, see our guide to the types of resin for 3D printing.

The Pros of Resin

- Incredible Smoothness: Resin printers use an LCD screen to cure entire layers at once with 35-micron precision. You cannot see the layer lines with the naked eye. The part looks like it came out of a factory mold.

- Isotropic Strength: FDM prints are weak between the layers (they can split apart). Resin prints are solid, uniform blocks of plastic. They are equally strong in all directions.

- Speed: A resin printer takes the same amount of time to print one rook or ten rooks, as long as they fit on the plate.

The Cons of Resin

- Lower Heat Resistance: Most ABS-like resins soften at around 50°C to 70°C. They cannot handle boiling water or hot car interiors unless you use specific high-temp resins.

- The Mess: You are dealing with sticky liquid chemicals. You need nitrile gloves, isopropyl alcohol, and paper towels. It is a messy process compared to handling a dry spool of filament.

Shop ABS Resins

Explore MoreHead-to-Head: Strength, Heat, and Detail

Let's look at the numbers. While "ABS-like" mimics the feel, the mechanical properties differ in key areas.

|

Feature |

ABS Filament |

ABS-Like Resin |

Winner |

|

Impact Strength |

High (Ductile) |

Medium-High |

Filament |

|

Heat Resistance (HDT) |

~95°C - 100°C |

~60°C - 80°C |

Filament |

|

Surface Detail |

Low (Visible lines) |

Very High (Smooth) |

Resin |

|

Ease of Printing |

Hard (Warps easily) |

Medium (Chemical safety) |

Resin |

|

Cost per Part |

Cheap |

Moderate |

Filament |

ABS Like Resin vs ABS Filament: Which One Fits Your Workflow?

1. Mechanical Strength (Toughness)

If you need a bracket to hold a heavy shelf, go with ABS filament. It has superior impact resistance. It will stretch before it snaps.

However, modern resins are catching up fast. Siraya Tech "Fast" resin is designed to be a daily driver that isn't brittle. It is perfect for tabletop miniatures that get handled often.

If you need extreme toughness in resin, you can look at specialized "Engineering" resins like Siraya Tech Blu. This moves beyond "ABS-like" and starts competing with nylon.

👉 For more info on handling these tough materials, see our Fast Resin User Guide.

2. Resolution and Aesthetics

This is where resin destroys filament. There is no contest. If you are printing a miniature character, a jewelry prototype, or a highly detailed prop, ABS-like resin is the only choice.

Filament printers leave visible layer lines that look like a topographical map. Resin printers create smooth curves.

If you plan to paint your model, resin saves you hours of work. You don't need to use filler primer or sand the model for hours. You just prime it and paint it.

3. The Workflow (The "Hassle" Factor)

This is often the deciding factor for beginners. How much mess can you tolerate?

Filament Workflow: You load the spool. You hit print. You wait. You pop the part off the plate. You remove support structures with pliers.

The Pain: Tuning the printer to stop warping. If the bed isn't perfectly level or the enclosure isn't warm enough, the print fails.

Resin Workflow: You pour the liquid. You hit print. You wait. You put on gloves. You scrape the dripping part off the plate. You wash it in alcohol. You cure it under UV light. You remove supports.

The Pain: The chemicals. You need a dedicated workspace. You cannot do this on your kitchen table. If you are new to this, read our guide on how to clean resin prints properly to avoid a sticky mess.

4. Print Failures

The two materials fail for different reasons. ABS filament fails because of physics (cooling shrinkage). The corners peel up, and the print head knocks the part over. Resin fails because of suction forces.

If you print a large solid block in resin, the vacuum force between the part and the film can rip the print off the plate. We cover this extensively in our article on troubleshooting resin support breakage.

Special Considerations for Resin Users

If you choose to go the resin route because you love the detail, there are a few things you need to know to get that "ABS" feel.

Viscosity and Temperature

Tough resins are thicker than standard resins. They flow like honey, not like milk. This means they need to be warm to print well. If your workshop is cold (below 20°C or 68°F), the resin will be too thick, and the print will fail.

You might need a small heater for your printer. Read our tips for printing with high-viscosity resins to master the process.

The Price of Quality

Historically, resin was expensive. But that has changed. We call it the Resin Renaissance. High-quality ABS-like resins are now very affordable, making them a viable option for everyday printing, not just high-end prototyping.

Beyond ABS

One cool thing about resin is the variety of specialty additives. You can get rubber-like resin, ceramic-like resin, or even glow-in-the-dark resin. Filament has options too, but mixing custom properties is often easier in liquid form.

Which Material is Right for You?

Choose ABS Filament If:

- You are making parts for a car, engine bay, or outdoor use (high heat is required).

- You need functional mechanical parts like gears, snap-fits, or casings that take abuse.

- You have an enclosed printer and proper ventilation for fumes.

- You don't care about visible layer lines or plan to sand them anyway.

Choose ABS-Like Resin If:

- You want smooth, professional-looking prototypes right out of the machine.

- You are making detailed figures, statues, or cosplay props that need to look realistic.

- You want isotropic strength (parts that won't split along layer lines).

- You need speed. Resin prints the whole layer at once, so printing 10 items takes the same time as printing 1.

Conclusion

The battle of abs like resin vs abs filament isn't really a battle. It is a choice between two different tools for two different jobs. It comes down to one question: Do you need heat resistance, or do you need beauty?

If you are engineering a mounting bracket for a hot engine bay or a structural part for a printer, stick to the real deal—ABS filament. It handles the heat that resin simply can't.

But if you are a designer, artist, or prototyper who needs parts that look finished right out of the machine and can take a beating, ABS-like resin is the modern miracle you have been waiting for. It combines the incredible detail of SLA printing with the toughness of real plastic. It allows you to make products that look and feel real.

Don't be afraid to experiment. Many advanced makers have both types of printers to cover all bases. Start with a bottle of ABS-like resin and see just how strong liquid plastic can be.

Need tough parts that look amazing?

Shop Best ABS-Like ResinFAQs About ABS Like Resin vs ABS Filament

Is ABS-like resin toxic?

Like all UV resins, it is a skin irritant and toxic to aquatic life in its liquid form. You must wear nitrile gloves and work in a ventilated area. Once fully cured and hardened, it is safe to handle with bare hands. However, we do not recommend it for food contact unless coated with a food-safe epoxy.

Can I mix ABS-like resin with other resins?

Yes! This is a pro strategy. Many users mix extremely tough resins (like Siraya Tech Blu) with standard ABS-like resins (like Fast) to create a custom blend. For example, mixing 10% Tenacious (flexible) into Fast Grey creates a "super-tough" ABS-like material that is almost unbreakable.

Is ABS filament waterproof?

Yes, the plastic itself is waterproof. However, FDM prints contain tiny microscopic gaps between the layers. Water can seep through these gaps under pressure. For a truly watertight seal, resin is often better because it forms a solid, non-porous cross-linked structure.

Does ABS-like resin smell?

It has a distinct chemical odor, but it is generally less pungent than the "burning plastic" smell of ABS filament. Newer formulas are reducing the odor significantly, but you should still keep an air purifier nearby.

Why is my ABS-like resin print brittle?

If your "tough" resin feels brittle, you likely over-cured it. UV light hardens resin, but too much UV light makes it brittle. Check your curing times. It could also be that you cleaned it in alcohol for too long, which can dry out the plastic.